Please note that this post may contain affiliate links and any sales made through such links will reward me a small commission – at no extra cost for you..

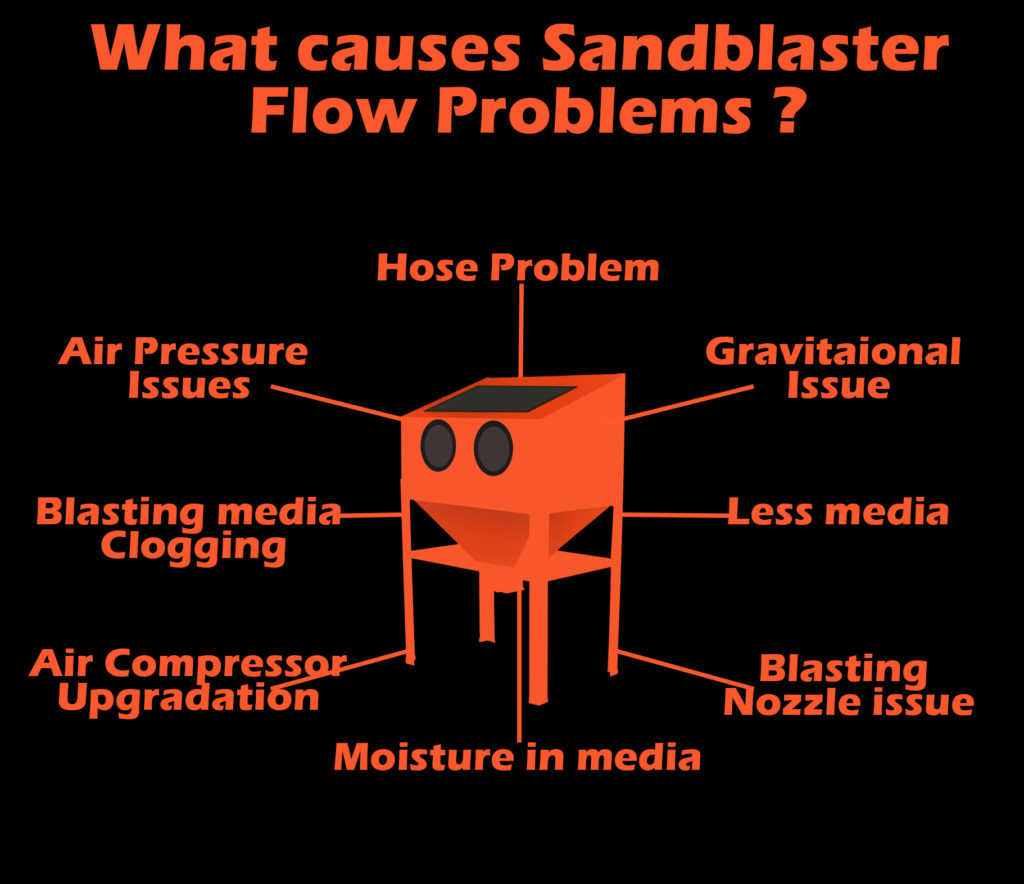

The most common problems with some of the sandblasters are that they usually have flow problems and want to know how to fix sandblaster flow problems?

Today we are going to help you out of it.

The most common type of sandblaster you usually see is Gravity / Siphon based and others are compressed air based. Now first of all we will show we will tell you what is the reason that these sandblasters have flow problems.

Table of Contents

1) Air Pressure Issues :

The first reason that your Sandblaster flow is not proper can be due to air pressure, you may not be getting the proper air pressure required by your sandblaster.

1st check your air pressure gauge, Read your user manual and see if you are getting the desired air pressure required by your sandblaster. If still, the sandblaster is not giving the desired pressure then check maybe your air compressor has decided not to work anymore or your sandblaster has some problems.

By the way, if you are thinking to replace your sandblaster I have Reviewed best sandblaster for cars here.

2) Air Compressor Upgradation :

If you are using an Industrial Sandblaster then you might need a large air compressor and also need to have a large Air multistage drying system.

Now if you are thinking that what is that these sandblasters use water and air mixture to make this sandblasting effective, this system sends Air, Sand & water mixture with high pressure and it removes the paint or rust easily.

Now if you don’t have these types of sandblaster then you should check your sandblasters requirement as what kind of Air Compressor it requires. you can easily find the requirement on the user manual.

If you fulfill the requirement demanded by your sandblaster then you should check the compressor as it might be having some problem with it. The last option is only to upgrade it.

3) Blasting media Clogging

Media Clogging is the most common issue that we have seen in most of the sandblasters, the clogging we see is usually due to low pressure or not the proper use of the suitable media recommended by the manufacturer.

To see what kind of blasting media is recommended by your manufacturer you should see the user manual or the product on amazon you find information there.

Another thing you should see is the grit size supported by your sandblaster, for this, you can also see the manufacturer user manual or the product on Amazon or other online stores.

Another thing is that sometimes a when a blasting media is not coming out properly try to shake your sandblaster sometime this thing also works for some sandblaster.

4)Moisture in media

Another most common problem is moisture in media, due to moisture in your sandblasting sometime the sandblaster gets clogged and it would not work efficiently.

Moisture usually due to environmental factors or can be due to other factors but you dont need to worry we are not here to identify your problems only we are here to give you the solutions too.

so if you have for some reason got moisture in your media than there are 2 options you can go for if you have an Oven you can bake your sanding media in it for some time and it would remove all the moisture from your media and you would be ready to go with your sandblaster.

Now if you don’t have an oven no need to worry if you have plenty of time you can utilize heat from sun put your blasting sand in a big bucket or if you have an open area you can use it, spread the sand and let it sit in sun for a day hope so it would do the job

5) Gravitational Issue

The most common issue with the gravity/based sandblaster is that they usually have gravity issues now by gravity issues I mean is that these sandblaster are not compressed air based so they have to be fed by gravity.

some sandblaster have seen to been needing more gravity than Other and for that you had to keep them on top of something & being on ground level was not sufficient.

what I would suggest is if you have bought a sandblaster with this kind of issue you would need a long hose and it’s not going to be easy to move around and it would be a wise decision to upgrade it.

6) Less media

Another issue is that fewer media in the sandblaster can cause flow problems in the sandblaster. Now why this can cause a problem is because if you are reusing the media it would eventually get shaped into smaller particles and then it may not be as effective as it was before and its flow will also be disturbed.

and make sure before sandblasting that you should check how much of sandblasting media do you actually have inside of it if you see that the air is properly coming out but the media is not then either you need to adjust the flow from the nozzle or you need to add more media into it.

7) Blasting Nozzle issue

Blasting nozzles are the key component of any sandblaster these nozzles wear out with the passage and of time and use. because the blasting media passes through the nozzles at high speed which in result wears out the nozzles. When the nozzles wears out than the it would push more blasting media through it and would require more air pressure so it would be better to change your blasting nozzle.

Now if you are using a good brand sandblaster they usually provide more than 1 nozzle for your sandblasting gun so you don’t have to buy every time.

Some brands do provide ceramic or other material nozzles so if you have then you don’t need to buy one and simply replace it. It will solve your nozzle issues.

8) Hose problem

Another reason why your sandblaster is having flow problems can be due to problem with your hose. If you are facing such problem

make sure that your hose does not get bend while using it as it may restrict your sandblasting media flow. The Other thing is that you should check a leak in your hose because if there is a leak then the air pressure won’t be coming out as efficient as it can.

Don’t try to tape your leak as the air pressure is a much higher volume that the tape won’t be able to hold it for a longer period, the best option you can opt for is to replace your hose.

we hope so we have addressed all the issues mentioned above, but still if there is any issue that you think we have not covered you can let us know at our contact us page.

-

Clogged Nozzle: A partially blocked nozzle can disrupt the flow of abrasive material.

-

Moisture in the Air Line: Water or condensation in the air compressor can cause irregular air pressure.

-

Insufficient Air Supply: If the compressor isn’t providing consistent air pressure or volume, pulsing may occur.

-

Worn or Damaged Parts: A worn nozzle, hose, or other components can lead to inconsistent performance.

-

Improper Abrasive Flow: Too much or too little abrasive material can cause pulsing.

-

Clogged nozzle?

A blocked nozzle is the #1 culprit. Sand can clump or debris might be stuck. Try removing the nozzle and giving it a good rinse. Think of it like a straw clogged with a gummy bear—no airflow, no sand! -

Air pressure issues?

Sandblasters need serious air pressure. If your compressor’s PSI is too low, the sand won’t blast. Check your compressor’s gauge and adjust it to the blaster’s recommended PSI (usually 80–120 PSI). Pro tip: Always double-check your hose connections—leaks steal power! -

Empty sand supply?

Sounds obvious, but… is your hopper actually full? If it’s running on fumes, the blaster’s just blowing hot air. Refill it with the right grit (too fine, and it’ll clog; too coarse, and it’ll wear out your nozzle faster). -

Valve malfunction?

The valve that controls sand flow might be jammed or broken. Give it a gentle tap with a rubber mallet to dislodge any grit. If that doesn’t work, it might need cleaning or replacement. -

Worn parts?

Over time, seals, hoses, or the internal valve can degrade. Inspect for cracks, tears, or leaks. Replacement parts are usually affordable and easy to swap.

-

Air pressure fluctuations

Your compressor might be struggling to keep up. If it’s too small or the tank is draining faster than it refills, pressure drops, causing the blaster to surge. Check:-

Is your compressor rated for your blaster’s PSI/CFM needs? (Most need 80–120 PSI and 10+ CFM.)

-

Are there leaks in your air hose? (Listen for hissing or feel for vibrations.)

-

Is the regulator set correctly? (A loose knob can cause wobbly pressure.)

-

-

Clogged or inconsistent sand flow

Wet, clumpy, or dirty sand is a surging villain. Here’s what to do:-

Sift your sand through a screen to remove clumps.

-

Use dry, clean grit (moisture makes it stick!).

-

Check the hopper’s agitator—is it spinning? If it’s stuck, sand feeds unevenly.

-

-

Worn or dirty parts

Over time, seals, valves, or nozzles wear out or get gunked up.-

Inspect the nozzle for partial clogs (use a wire brush to clean).

-

Check the internal valve—worn seals here cause pressure leaks.

-

Replace O-rings or worn seals (they’re cheap and easy to swap).

-

-

Operator technique

Sometimes, the issue is how you’re holding the trigger. A shaky grip or jerky movements can mimic surging. Try:-

Pressing the trigger smoothly and steadily.

-

Moving the gun in slow, controlled passes.

-

tent